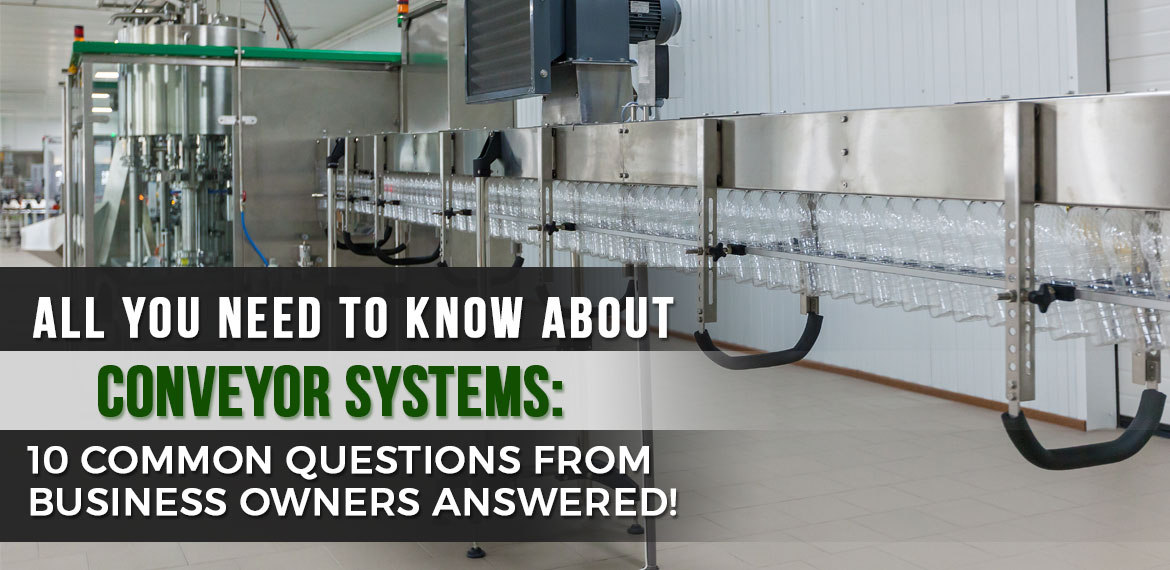

If you’re considering purchasing a conveyor system for your facility in the Philippines, you may have a few questions about conveyors on your mind. For example, how exactly will your facility benefit from a conveyor system? Or how will you deal with repairs down the line? You may also want to determine the type of conveyor system that best suits your business applications.

Fortunately, these are all common questions which several business owners in the Philippines have asked before. To cater to your queries and give you an overview of conveyor systems at once, here are 10 questions about conveyor systems answered.

10 Common Questions About Conveyor Systems Answered

1. What Are the Advantages of a Conveyor System?

Despite their upfront costs, conveyor belts offer several benefits to facilities in the Philippines:

-

-

- Lower Labor Costs. Conveyor systems are more efficient than forklifts, carts, or manual transport. They also reduce the number of people required to move a certain item. As a result, you’ll spend less on the labor it takes to transport goods.

-

-

-

- Higher Throughput. The constant movement of conveyor systems can certainly increase the number of delivered items for any operation. This will help your facility hit deadlines and production quotas with ease.

-

-

-

- Efficient Usage of Floor Space. Conveyor systems can be mounted on the floor, on the ceiling, and on different levels of your facility. There are also vertical conveyors which can move items from one level to the next. Lay out your system properly, and you’ll be freeing up floor space. Your only limit will be the height of your facility.

-

-

-

- Less Errors. Conveyor systems’ standardization and sorting capabilities can streamline your operations by cutting down on rework and errors.

-

-

-

- Controlled Pace. You can speed up or slow down the movement of goods along your assembly line with the use of conveyor systems. Use this to create work buffers for steady production with minimal downtime or wastage.

-

-

-

- Increased Safety. Install conveyor systems in your facility, and you’ll be able to reduce on-site forklift traffic. Your employees will no longer have to lift objects and strain themselves as much, either.

-

-

-

- Versatility. Depending on the specific equipment, a conveyor system can reverse direction, change heights, or rotate items. You can also use conveyor belts for receiving and returning goods.

-

2. How Do I Choose a Suitable Conveyor System?

You’ll mainly be choosing between pre-existing or turnkey systems and custom solutions built from scratch. Turnkey systems offer the following advantages to companies in the Philippines:

-

-

- More cost-efficient

- Easier and faster to install

- Feature-rich by default

- Less risky for personnel who lack in-depth technological knowledge

-

Custom solutions have their own strengths as well, however:

-

-

- Tailored to each facility

- Competitive due to customization

- Can be installed phase by phase (i.e. essentials first, accessories later)

- Easily scalable and adaptable

-

After deciding whether you’ll invest in a turnkey or custom solution, you’ll need to choose a specific type of conveyor system. Here are some guide questions to ask yourself:

-

-

- What will the conveyor system be used for? Will it simply transport cargo, carry items through sterilization processes, or sort finished goods? Your answer to this question will influence the type of conveyor belt your facility needs.

- What material will be transported? Will you be transporting grains, wood chips, balikbayan boxes, or fresh produce? The specific items you’ll be transporting will determine whether you need specialty belting.

- How strong should the motor be? If you’ll be moving heavy loads or transporting goods at higher speeds, you’ll need a powerful conveyor system motor.

- Do I have floor space for a given type of conveyor system? Be sure that even with the new conveyor system, there’ll still be room for other processes in your facility.

-

3. How Often Should I Inspect the Conveyor System?

Ideally, you should inspect your conveyor system at the start and end of each shift. Walk around and do a visual inspection while letting the system run. Watch out for odd noises and vibrations, and pay attention to the condition of running parts.

4. Which Conveyor System Components Need the Most Attention?

You’ll want to keep an eye on bearings, belts, magnetic slider beds, magnets, motor covers, and motors themselves. Here are indications and instructions for each:

-

-

- Bearings. These often wear down due to heat. If a bearing is either glowing or hot to the touch, it needs maintenance. Also, if it lacks grease upon inspection, the bearing either needs additional grease or has already failed.

- Belt. Regularly check if your belt/chain still has the right tension to operate efficiently. Clear any jammed pieces of scrap as well. Have the belt repaired if less than 25% of its width is damaged. However, if a large part of the belt has is torn or burnt, you’ll need to replace it.

- Magnetic Slider Bed. An easy way to check a magnetic slide conveyor for indentations is to lay a long straight edge on the surface. You may also see boot prints or dents at first glance. Other indications of damage are thumping sounds during conveyor operation. This sound comes from magnets under the bed hitting the indentations as they travel.

- Magnets. If a magnetic slider bed has indentations, you’ll want to check the magnets themselves as well. The magnets’ stainless steel cover may wear down after some time, causing the magnets to jam the conveyor.

- Motor Covers. Scrap material often builds up on motor covers. Clear the covers out regularly.

- Motor. A warm motor is still functional, while an overheated motor should be replaced. This component tends to break without warning, but you may be able to catch the smell of an overheating motor and replace it early.

-

In some cases, the sound or vibrations of an operating conveyor belt can give away underlying problems.

5. How Long Should a Conveyor Belt Last?

The lifespan of your conveyor belt will depend on your application. A conveyor system in an extreme environment may need a new belt every few weeks. On the other hand, a belt can last over 10 years given ideal operating conditions and proper maintenance.

TIP: Increase your belt’s lifespan by storing it properly. Roll it up and store it off the floor in a cool, dry, dark area.

6. How Do I Integrate a Conveyor System Into Existing Operations?

Your best bet is to leave system integration to a reliable supplier in the Philippines. However, you can certainly help by providing necessary information, such as facility floor plans and specifications of existing equipment. Give as many details as you can to ensure smooth integration.

7. What Are the Most Common Issues With Conveyor Systems?

Conveyor systems can be affected by two main issues, both of which are easy to remedy:

-

-

- Lack of Foresight. A poorly planned conveyor system will be unable to adapt to changes, process disruptions, or new products. When choosing a conveyor system, be sure to include scalability in the picture.

- Poor Maintenance. Even the best systems will break down quickly if they are not maintained well. New personnel should know how to take care of the system and use it properly.

-

Most other issues with conveyor systems can be traced back to either or both of these two problems.

8. How Do I Know Whether to Repair or Replace a Conveyor System?

Different companies will have different answers to this question. Some companies in the Philippines base their decision on costs. For example, they’ll often replace an entire system if the repairs exceed 60-70% of the replacement expenses. Others prioritize lead time, choosing repairs if they can’t afford to wait for over a month to have a replacement delivered.

You’ll have to figure out what works for your company. Start by determining whether you’ll place more weight on expenses or lead time. Then, determine your threshold from there.

9. How Do I Handle Repairs?

Follow these steps if your conveyor system needs repairs:

-

-

- Find Out the Degree of Damage. This will give you a rough idea of how much time and resources repairs will take. A small tear in the belt can certainly be repaired faster than damage from a forklift collision. Consult with conveyor system experts in the Philippines for a more detailed assessment.

- Check Your Budget. Do you have enough funds for the repairs? If not, try tapping insurance and loans to cover the costs in the meantime.

- Ask if Supplies Are Readily Available. Your system’s downtime will increase if supplies or equipment for the repairs still need to be shipped over.

- Prepare Bypass Methods. You may need to rent a replacement conveyor system to keep production going despite repairs.

- Hire Experts. Although third-party professionals are an option, you should also ask your supplier in the Philippines if they have dedicated repairmen on hand.

-

10. How Do I Choose a Conveyor System Supplier?

There are several conveyor system suppliers in the Philippines nowadays, but you’ll want to be sure that you’re working with an industry expert. Here are some factors to consider:

-

-

- Expertise and In-Depth Knowledge. Find a conveyor system supplier who knows what they’re doing. Aside from providing top-notch service, an insightful supplier may even point you towards rising trends concerning production lines.

- Readily Available Technical Support. The best suppliers in the Philippines can be reached whenever you need them. They’ll also constantly have technicians on hand.

- Experience in Your Industry. Has your supplier worked with other companies in your industry? If so, they’ll know what exactly to do for your facility. They’ll also be able to advise you on the conveyor system issues you’ll face the most.

- On-Site Training. This equips your own employees with the necessary skills to handle quick repairs and train new hires easily. It’s also a good sign of a reliable supplier in the Philippines.

- Value For Your Money. Does this supplier often offer ways for you to save money or reduce downtime? Are they available 24/7? The answers to these questions can indicate a supplier’s reliability and true value. It helps if the supplier documents what they’ve done, so that you’ll have evidence that your company is actually saving money.

-

Bookmark this list of questions, and you’ll have a convenient guide to owning a conveyor system in the Philippines. However, anything beyond the basics will now depend on the specific equipment you’ll install in your facility. If you want to go into the technicalities, it’s best to inquire with an industry expert who has dealt with conveyor systems first-hand.

Elixir has been offering cutting-edge equipment and technical service to customers in the Philippines for over 25 years. Our solid ties with Philippine industrial firms and world-class manufacturers serve as proof of our in-depth expertise. Contact us today, and our professionals can answer any remaining questions you may have about conveyor systems.

Visit our blog regularly for more posts about conveyor systems and related industrial equipment.