Twisterbox

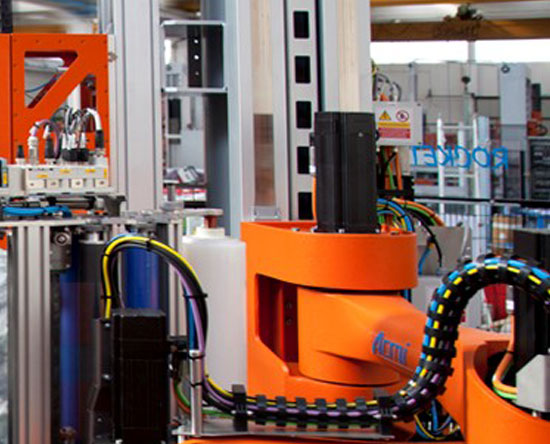

Twisterbox is a continuous layer formation system. This system consists of a series of robotic arms equipped with special grippers which move according to a specific programme that positions the packs and forms a complete layer. The layer is then transferred to the palletiser.

We can help you on your Inspection and Packaging needs. Get in touch with the Elixir team now!

ACMI S.p.A. is an Italian company specialized in the production of high technology bottling and packaging lines. The company, based in Fornovo Taro, in the province of Parma (Italy), started up as a manufacturer of palletisers and depalletisers for the food and beverage industry and went on to specialize in all packaging processes.

Palletizer

Use

Advantages

ACMI patented the Twisterbox system in 2002, revolutionizing the method of “layer formation”. The machine has been constantly improved over the years both mechanically and electronically. The experience gained from the numerous installations is a concrete advantage for the customer. Today the Twisterbox is presented with a new outer structure that makes it easier to access for operators and with new grippers made of special material that are able to move even faster in the work area. The format changeover operations are managed exclusively by software, without any manual intervention on the grippers or on the machine structure. Furthermore, ACMI mainly uses components that are easily found in the marketplace even by the customer, helping everyday maintenance and reducing waiting time for spare parts.

- Available with one, two or three gripping modules

- TT (Twisterbox Twin) configuration with twin grippers

- Top speed of 140,000 cans per hour with 2×2 packs

- Tray former function

- Possibility of performing product facing

- Perfect rotation and positioning

- No shock on the product

- Multiliner function

- Possibility of handling products with special shapes and fragile contents

- Suitable for handling PET bottles with ultrathin walls

- No maintenance

- Simple and fast format changeover procedure. No mechanical intervention by the operator

- Wide flexibility, the Twisterbox is suitable for high and low production levels

- Can be integrated with the entire range of ACMI palletisers