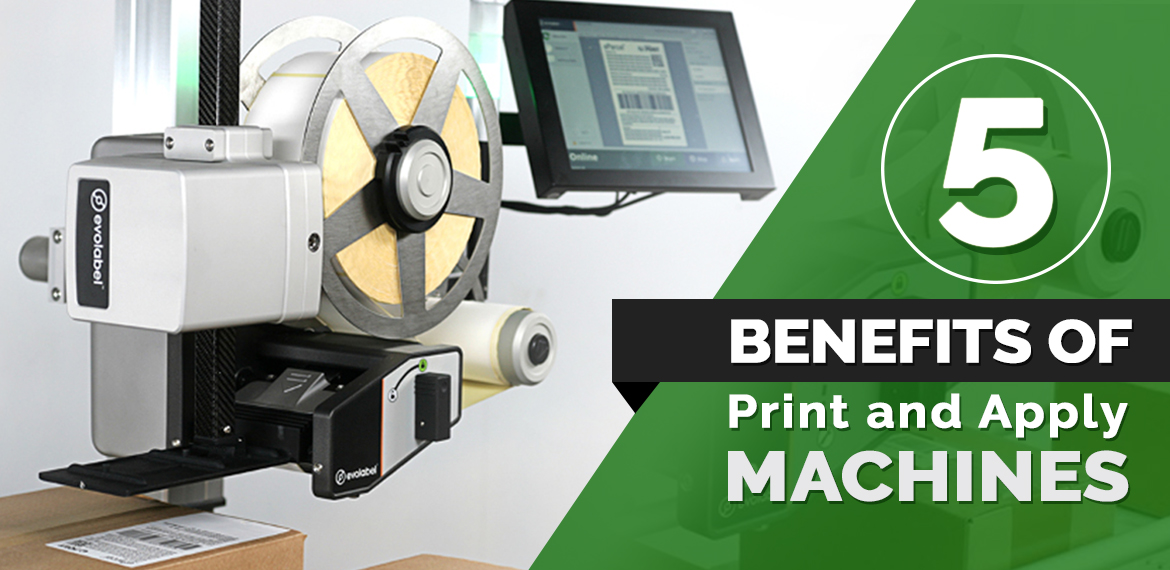

Regardless of your industry, your products most likely need labels. These can include shipping labels, QR codes, nutritional facts, warnings and uses, and serial numbers. You may need a lot of labels, depending on your packaging or your regular production volume.

Companies with tighter budgets may think that they can handle all their labelling applications without the help of a print and apply machine. However, automated labelers come with several benefits that far outweigh their initial costs. Here are 5 ways that print and apply label applicators can benefit your assembly line.

5 Ways Print and Apply Machines can Improve Your Assembly Line

1. Maximize Existing Labor

Fit your production line with print and apply machines, and you can free up your employees for more delicate tasks that require human skill. Automated labelers work non-stop and with little human supervision. With regular maintenance, a quality label applicator can serve its purpose on your line for years without adding to your labor costs.

TIP: For best results, be sure to pick a print and apply label applicator that is well-suited to your application. Some specifications to note down are the machine’s print speed and print width.

2. Maintain Consistency of Label Placement

Manual label application may be prone to inconsistencies, especially during extended operations or high-volume production. Human employees may find it repetitive and dull to peel off labels and stick them to products for hours on end. Plus, badly-placed labels may have to be removed and replaced, resulting in wasted time and material. Print and apply machines eliminate these problems and speed up label printing processes thanks to their accuracy.

3. Minimize Errors

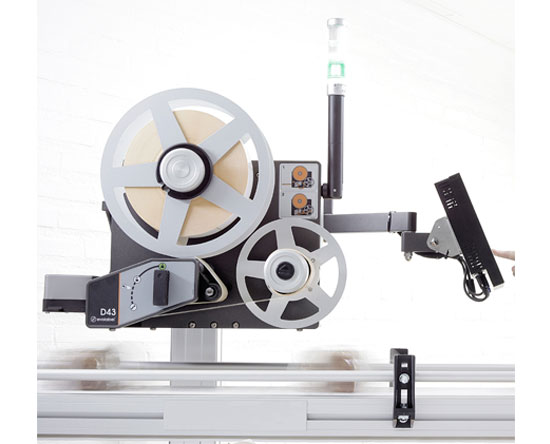

One misprinted or unreadable label might not seem like an issue at first. However, accumulated errors often result in a surprising amount of waste. To solve this, print and apply machines are designed to produce highly readable labels. Evolabel’s D43, T43, and T63 labelers can print text and codes at a resolution of 300 dpi, for example. Label machines may also come with verification features and media sensors to ensure error-free results.

4. Add Scalability to Your Production Line

As demand for your product increases, your operations may have to expand to keep up. A label machine with a high print speed is a cost-effective alternative to hiring additional labor. For instance, Evolabel print-and-apply machines often feature maximum print speeds of 200 mm/s.

5. Increase Profits

With the previous points in mind, print and apply machines can boost your production volume and help you optimize your workforce while greatly reducing errors and downtime. This all adds up to cost-efficiency and a higher return on investment.

Reap these 5 benefits by installing print and apply machines on your assembly line. Before finalizing any purchases, however, it’s advisable for you to get insight from an industry expert who can help you find the best label applicator for your packaging needs.

Elixir Industrial Equipment, Inc. has supplied its customers in the Philippines with world-class machines for 25 years and counting. Our product lineup includes print and apply machines from renowned Swedish company Evolabel. In addition, we provide complete post-sales service, from installation to repairs, for our customers’ utmost convenience. Contact us today to find out more.

Visit our blog regularly for more posts about packaging machines and related industrial equipment.