Your company might be thinking of engaging a packaging company in the Philippines to get a new production line or give your current line an overhaul. Of course, you need to plan things out first. This includes taking note of what packaging machines you have to include for smooth assembly processes. To get you started, here’s a list of 10 kinds of packaging machines you might need on your production line.

10 Essential Kinds of Packaging Machines

1. Carbonators and Pasteurizers

Carbonators infuse beverages with carbon dioxide for a bubbly texture, while pasteurizers kill off E. coli and other spoilage organisms. Certain pasteurizers, including some packing machines offered by TMCI Padovan, can process starch and sweetener aside from wine, grape juice, and dairy products.

2. Filling and Bottling Machines

Filling machines pour grains, liquids, and other products into pre-made containers. Meanwhile, bottling machines are usually designed for particular beverages–the Matrix TECNA G-V for example is built to handle flat wine. Accuracy is important for these packing machines, which must consistently fill thousands of containers to a certain level. They are often accompanied by fill level inspection machines such as the Miho Newton Optic 2 for quality control.

3. Sterilization Machines

Sterilization machines get rid of transmissible agents such as bacteria, viruses, and spores to prevent consumable products from becoming contaminated. This type of packing machine ensures that the products enter the market smoothly and don’t wind up posing a threat to consumers.

4. Heat Sealing Machines

Products often need to be protected against tampering or contamination, especially in food or pharmaceutical applications, hence the need for packing machines that serve as sealers. Heat sealing machines melt plastic film or adhesive together to seal a package. In addition, some sealers also have shrink wrapping capabilities, vacuuming air from the package before sealing to ensure a tight fit.

5. Strapping and Bundling Machines

Lumber and metal rods need to be secured into bundles, while heavy boxes should be strapped aside from being taped shut. This kind of packing machine makes transport easier and prevents products from taking damage or causing injury during shipping.

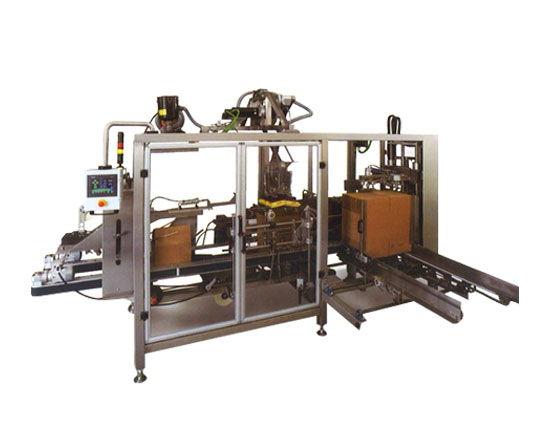

6. Case Packers

Aside from being time-consuming, manual packing can lead to repetitive strain and other injuries in assembly line employees. With the help of a case packing machine, companies can have their employees focus on more skill-heavy work and speed up the packing process at the same time. Some case packers can go up to 50 picks per minute.

7. Case Erectors

These machines can erect boxes quickly, saving time on your assembly line. They go hand in hand with case sealers, which apply tape or glue to the box. Some packing machines merge erectors and sealers. Trident Pack’s 3-in-1 case packer in particular combines erecting, packing, and sealing capabilities in a single piece of equipment.

8. Labelling Machines

A quality product ought to have a quality label to go with it, both to identify the product and to provide important information to consumers. Evolabel’s lineup of print-and-apply machines use thermal technology to produce high-resolution labels, whether an assembly line needs direct thermal printers which can cover a wide range of labelling applications or thermal transfer printer for more durable and long-lasting print.

9. Coders and Printers

Product coders such as those manufactured by Linx UK can print logos, QR codes, date codes, and more onto all kinds of surfaces. Laser coders in particular are handy for producing anti-counterfeiting marks on premium products.

10. Palletizers

An assembly line fitted with a reliable palletizer can minimize the time it takes for a freshly packed product to enter the market. Packing machines like Trident Pack’s compact palletizer boast 4 axes of motion and servo motors for added precision.

ALSO READ: Cobot Basics: 5 Ways Collaborative Robots Can Improve Your Assembly Line

Have you noted the types of equipment you’ll be needing? Ideally, your next step should be to ask for expert help to ensure that you end up with an efficient and reliable production line.

For the past 25 years, Elixir Industrial Equipment, Inc. has provided its customers in the Philippines with high-quality packaging machines from international manufacturers. We also offer complete post-sales service, which includes training customers on basic machine operation, troubleshooting, and maintenance. Contact us today to find out more!

Visit our blog regularly to read more posts about packaging equipment and other assembly line machines.