Fenix

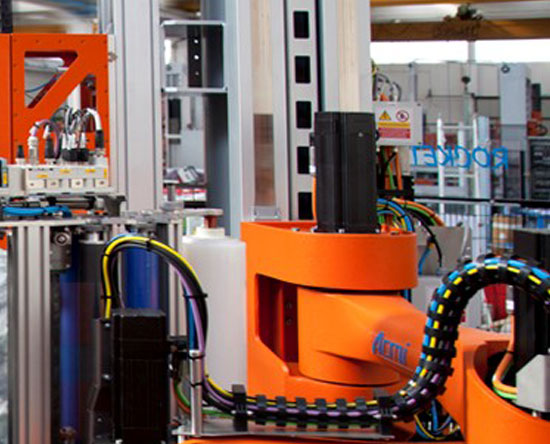

Fenix is the name of the shrink wrappers “Made in ACMI”. These machines have the task of packaging together several units of product using shrink wrap film or suitable trays. The products packed in this way form the “pack” which is then transferred to the palletisation phase.

We can help you on your Inspection and Packaging needs. Get in touch with the Elixir team now!

ACMI

ACMI S.p.A. is an Italian company specialized in the production of high technology bottling and packaging lines. The company, based in Fornovo Taro, in the province of Parma (Italy), started up as a manufacturer of palletisers and depalletisers for the food and beverage industry and went on to specialize in all packaging processes.

Type

Shrinkwrapper

Use

The packaging phase can be carried out with four different systems: by means of shrink wrap film, a flat interlayer with shrink wrap film, trays and, finally, trays with shrink wrap film. Using the most suitable of the above-mentioned systems, the Fenix shrink wrapper is able to pack any type of container belonging to the beverage or food sector like, for example, PET bottles of any shape or size, cans, jars, etc. The shrink wrapper is an essential machine for the correct and rational handling of the container which, coming out of the filling phase, needs to be grouped and joined properly. This procedure, of course, improves the subsequent product storage and shipping phases as well as its visibility on the shop shelf.

Advantages

ACMI designs and manufactures high efficiency shrink wrappers. High performance, robust construction, reliability and a prompt after-sales service are the hallmarks of the Fenix range. The design is carried out by a team dedicated exclusively to the development of this machine. This assures the customer that they are purchasing a machine that is always at the forefront of technology with regular mechanical and software updates. ACMI is also aware of the requirements of the operators working on the production line. This focus results in an intuitive touch screen control panel, easy accessibility to the parts subject to routine intervention and highly simplified format changeover operations. Finally, thanks to the choice of using standard high quality components, ACMI frees the customer from the costly dependence in terms of spare parts and materials for ordinary and extraordinary maintenance of the machine and ensures a certain degree of autonomy in case of urgent interventions.

- Available with one, two or three lanes

- Top speed of 100 packs per minute (for each lane)

- Film only; interlayer+film; tray; tray+film

- Low consumption oven resistances

- Self-lubricating chains and devices

- Simple and fast format changeover operations

- Automatic film changeover system with external reel carrier box

- The film unwinder is controlled electronically

- In the event of a black-out the machine does not require re-phasing

- Ventilated conveyors at the oven outfeed

- Automatic shutters at the oven infeed and outfeed

- The specific design allows the use of only one type of motor and inverter on the entire machine, thus reducing the cost of the spare parts warehouse managed by the customer

- No maintenance